Customized Zip Lock Bags: A Complete Guide Tailored for UK Brands

Do you struggle with navigating the complexities of ordering Customized Zip Lock Bags? This guide breaks down every critical step—from specifications to sustainability—ensuring your custom packaging project runs smoothly.

🔍 Step 1: Define Your Requirements

Clarify these essentials before production:

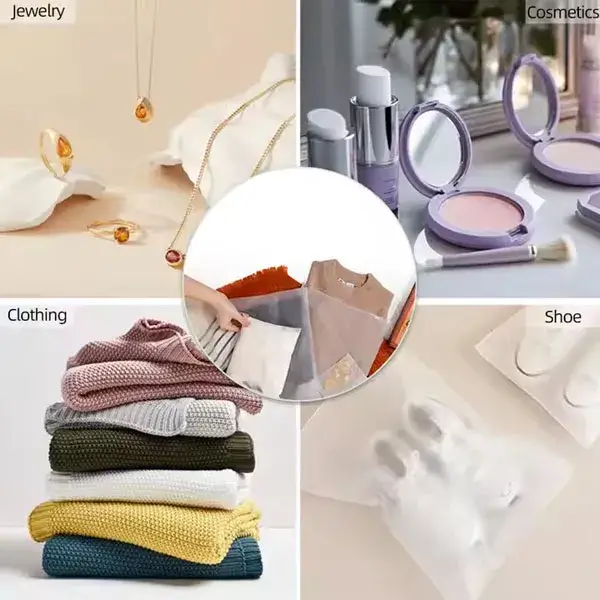

1.Primary Use Case

Food Packaging Bags: Must comply with EU/UK food-contact regulations (e.g., FDA-grade PE/LDPE). Prioritize moisture/oxygen barriers.

Clothing Packaging Bags: Opt for 8-10 micron tear-resistant PE with high clarity.

Industrial Items: Use 3.9Mil+ (0.1mm) thick films for heavy-duty protection.

2.Technical Specifications

Exact dimensions (L×W×Thickness), zipper type (standard/watertight/invisible), and bag style (three-side seal/stand-up pouch/die-cut handle).

3.Sustainability Needs

For compostable materials, choose certified PLA/PBAT blends (180-day soil decomposition).

Pro Tip: Download our free Custom Packaging Checklist to streamline briefings.

⚙️ Step 2: Material & Manufacturing Essentials

Performance hinges on material science:

| Material | Key Properties | Ideal Applications |

| PE/LDPE | Flexible, cost-effective | Clothing Packaging Bags, accessories |

| PP/OPP | Crystal clarity, rigidity | Retail displays, stationery |

| PET Laminates | Superior oxygen barrier | Coffee, dried snacks (Food Packaging) |

| Compostable PLA | EU-certified biodegradability | Organic brands, eco-products |

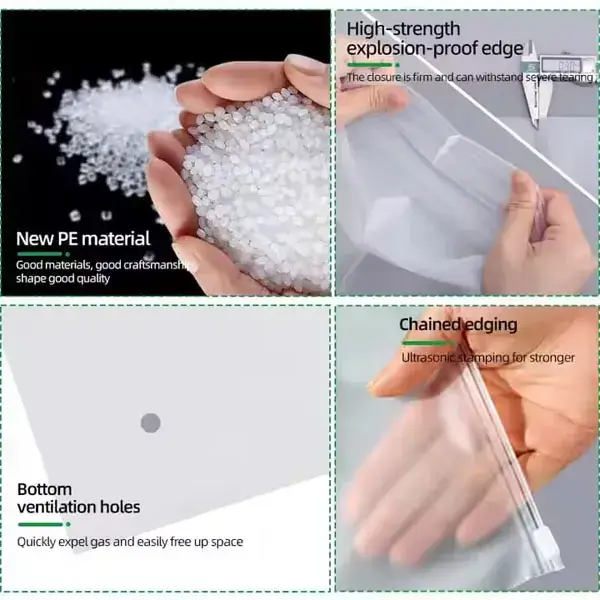

Critical Processes:

Heat Sealing: Ultrasonic sealing prevents delamination (seal strength >50N/50mm).

Zipper Molding: Monoblock injection for leak-proof closures.

🎨 Step 3: Design, Print & Quality Assurance

Transform branding into tangible assets:

Printing ProtocolsEco-solvent inks (heat-resistant to 120°C) to avoid smudging during bag-making.

Include 2mm bleed margins in artwork files.

Functional EnhancementsStand-up pouches: Reinforced base gussets for stability.

Tamper-evident zippers: Dual-track seals for high-value goods.

Non-Negotiable QC Tests:

24-hour water-inversion leak test.

Zipper peel strength ≥50N/50mm.

Material thickness tolerance ≤±0.02mm.

🏭 Why Partner with Experts for Customized Zip Lock Bags?

We solve your packaging pain points with end-to-end solutions:

✅ Full Material Portfolio: Food-safe PE to compostable PLA—all UK/EU compliant.

✅ Agile Production: 500-unit prototypes (3-day turnaround) + high-volume capacity.

✅ Deep Customization: Precision laser cutting + Logo Customization (foil stamping/screen print/embossing).

✅ Rigorous QC: 36-hour accelerated aging tests + SGS certifications.

Case Study: UK tea brand EcoSip boosted shelf impact by 40% and reduced carbon footprint by 65% using our Ariepack stand-up zip lock bags.

💎 Conclusion: Packaging as Brand Equity

Customized Zip Lock Bags amplify your brand’s voice while protecting products. From regulatory compliance to structural innovation, expertise matters. Our ISO 9001:2015-certified factory and dedicated team offer:

✨ Free design optimization

✨ UK warehouse distribution

✨ Dedicated project management

Request a Free Quote → Launch your custom packaging journey today!